Full-time at SP Product Development Cell

Several embedded control and power electronic applications developed.

After I graduated with a Bachelor’s in Electronics Engineering in May 2019, I worked for an year at the Product Development Cell of my institute with Dr. Y.S. Rao and Dr. Rajendra Sawant. We undertook consultancy projects from the industry, and I led the development of these projects with support from my professors and undergraduate student interns. I worked on four such projects during that time.

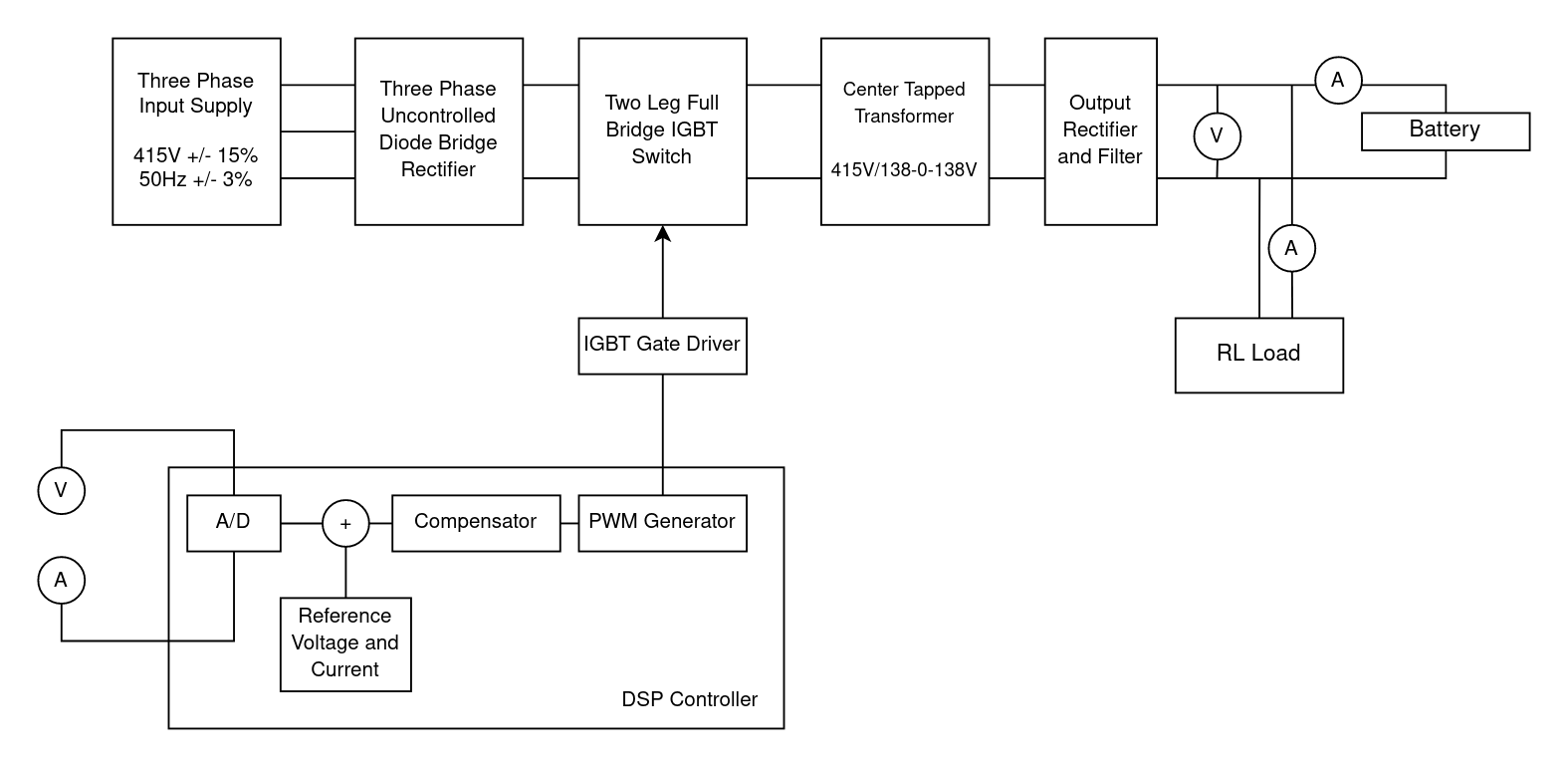

High Power Battery Charger

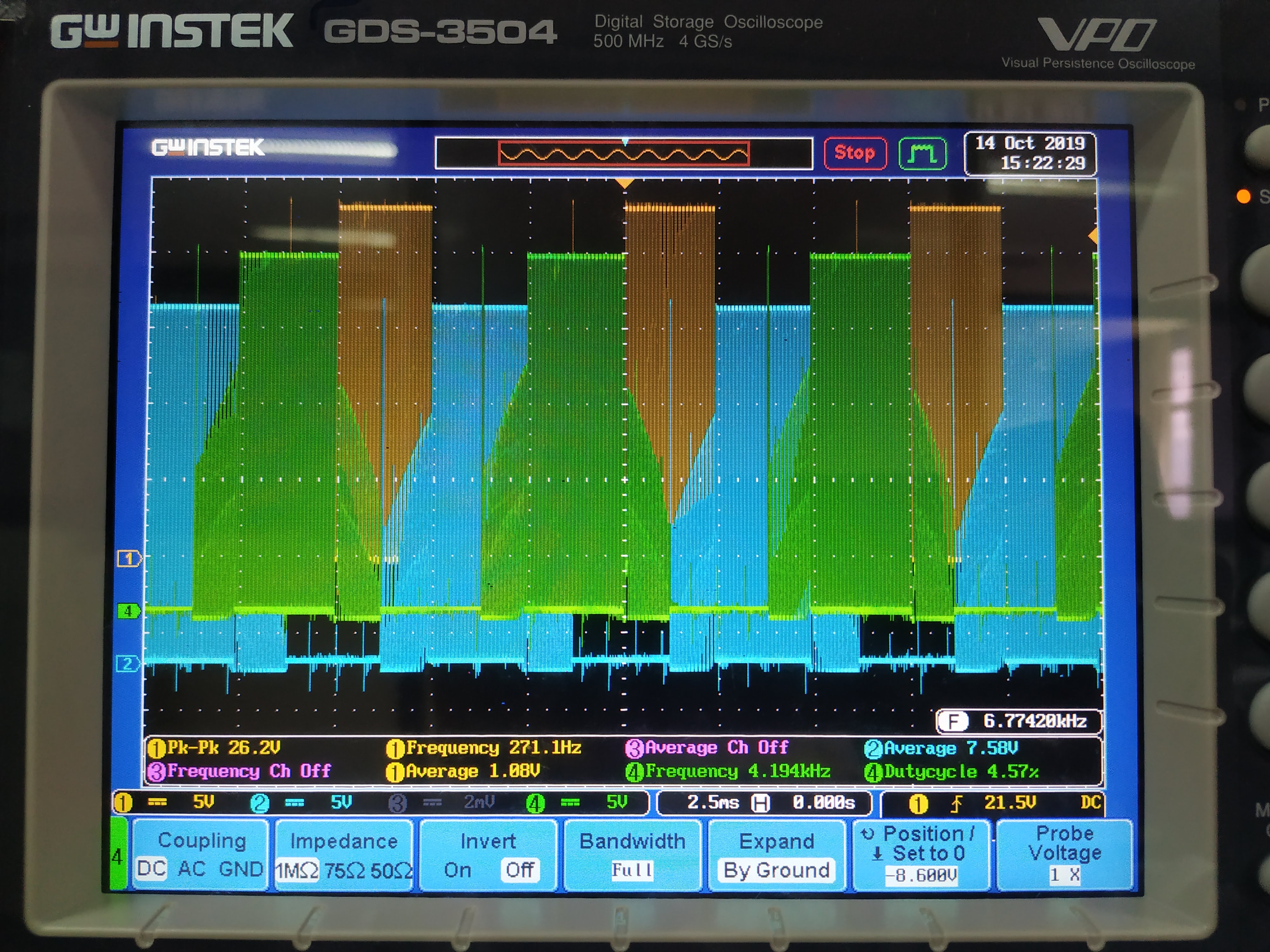

We developed a 4.5kW (135V, 25A) Battery Charger for the Indian Railways. The figure below shows a simplified block diagram of the system.

The system is controlled by a Texas Instruments C2000 series DSP, with which I learnt many aspects of writing robust embedded software. I would also get to engage in quality discussions with Prof. Sawant, who would happily explain me all the power electronic wizardry in play. When we needed to test our design calculations, we would even create our own transformers and inductors by wrapping wire around large 6 inch ferrite cores!

The final system worked well, and we tested out the constant voltage and constant current modes by using a large lamp load.

The video below shows a demonstration of the system’s short circuit protection. It is one of the few things I have implemented that have never failed to work! :D

[Insert video]

Digital Controller for Induction Casting Machine

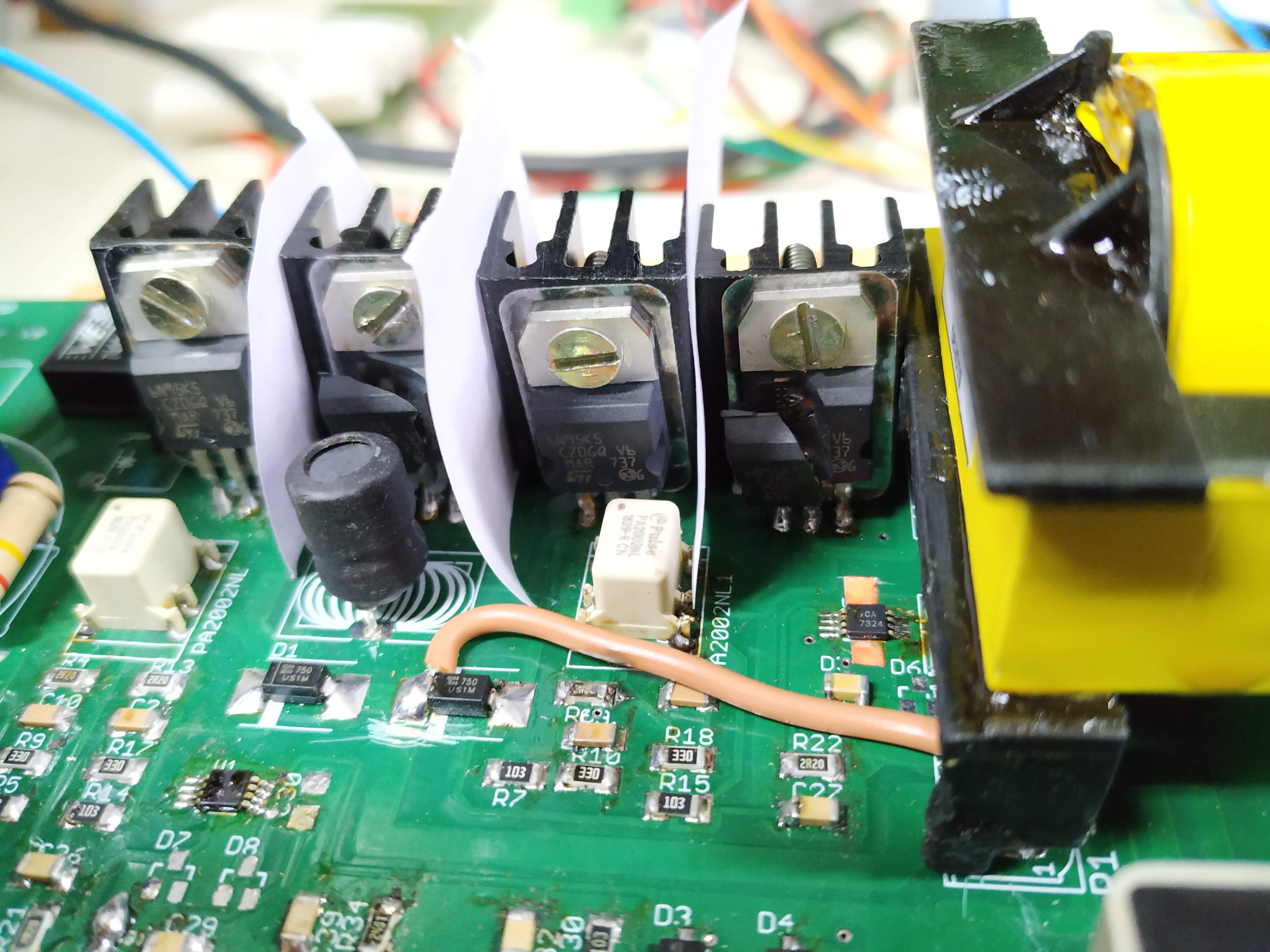

This machine is a 12kW induction heater which utilizes an IGBT based high frequency inverter. The hardware for this project was mostly ready and an early version was being tested at the time I joined the team. However, there were many issues like erratic button operation, sluggish control and random failures. I performed a complete overhaul of the embedded code, and also improved the physical circuit to make it more robust to noise.

Here is a video of our machine being used to recycle gold and silver jewelry. The factory workers were very happy after the machine was fixed.

[Insert Video]

It is fascinating to see your software and hardware - the tiny capacitors you added, the if and else statements - come together to melt metal and be actually used in a real world application! Hey, it almost certainly never works the first time around. But after many, many hours of modifications, the feeling when you know exactly how the code is internally jumping around, producing the humming noises, flashing lights, or motion that you can feel, see and hear - that is a joy that hardware brings; that software applications alone do not generate.

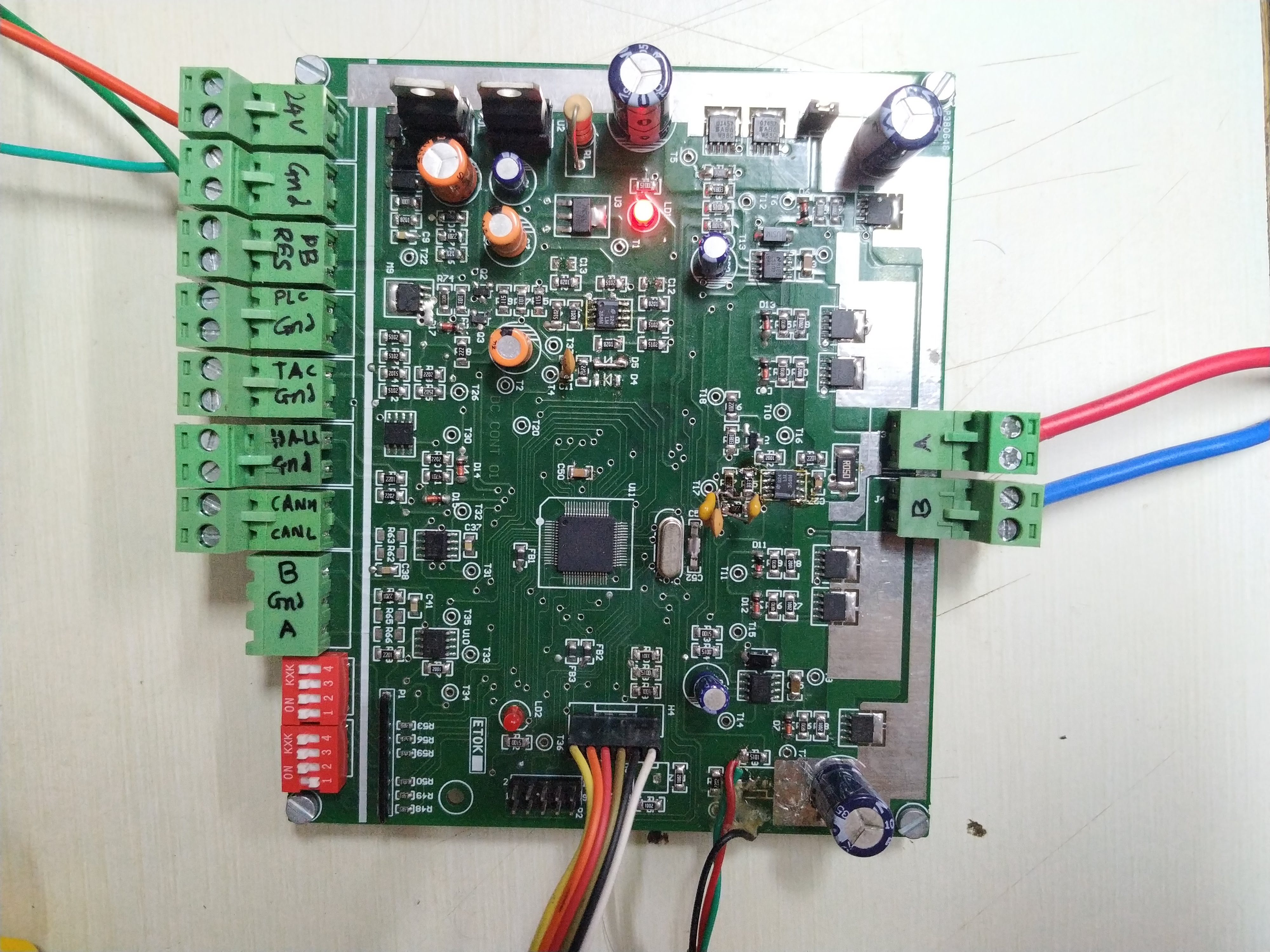

Brushed and Brushless DC Motor Drives

This is actually two different projects for separate contracts that we had, but the development followed a similar approach. Both these systems were based on the Microchip dsPIC series microcontrollers.

In this first one, we had to create a 24V/15A DC Motor Drive for a PMDC or Shunt DC Motor. I implemented speed and torque control loops for the motor with only the motor back EMF as feedback - no encoders for speed measurement.

We also had to develop the 24V/15A power supply used to power this system. That was a whole another adventure! I blew more MOSFETs than I could count!

The second project was to develop a Universal Controller for Solar Water Pump Motors ranging from 3HP to 10HP. These brushless DC motors are buried deep in the ground and are used to pump up water for agricultural applications. Because of this, it is better to not use any external sensors, like a hall effect encoder, and instead rely on the motor back EMF for motor speed control.

However, this back EMF control is much more complicated for a brushless DC motor. You see, for a simple PMDC motor, the back EMF is just averaged out, and motor speed can be varied depending on the magnitude of back EMF. But for a three phase brushless DC motor, for the motor to spin, each of the phases have to be excited precisely within a very narrow time frame - and this time frame can be estimated depending on when the back EMF signal crosses 0.

During my time working at the Product Development Cell, I could not see this project to completion. I was able to spin up a small brushless motor using just the back EMF, but I did not have the time to implement the startup sequence necessary to get these motors spinning before back EMF control kicks in.

Closing Thoughts

Choosing to work at PDC was one of the best decisions I’ve made. I made some wonderful friends, evolved greatly as an engineer, learnt ways to be a good mentor, and even met a very special person ;). Thank you Prof. Sawant and Prof. Rao for making this possible, I am indebted to you!